Phan Quoc Khang Nguyen

Higher Degree Research

Predicting Material Properties of Additively Manufactured Acrylonitrile Butadiene Styrene via a Multiscale Analysis Process

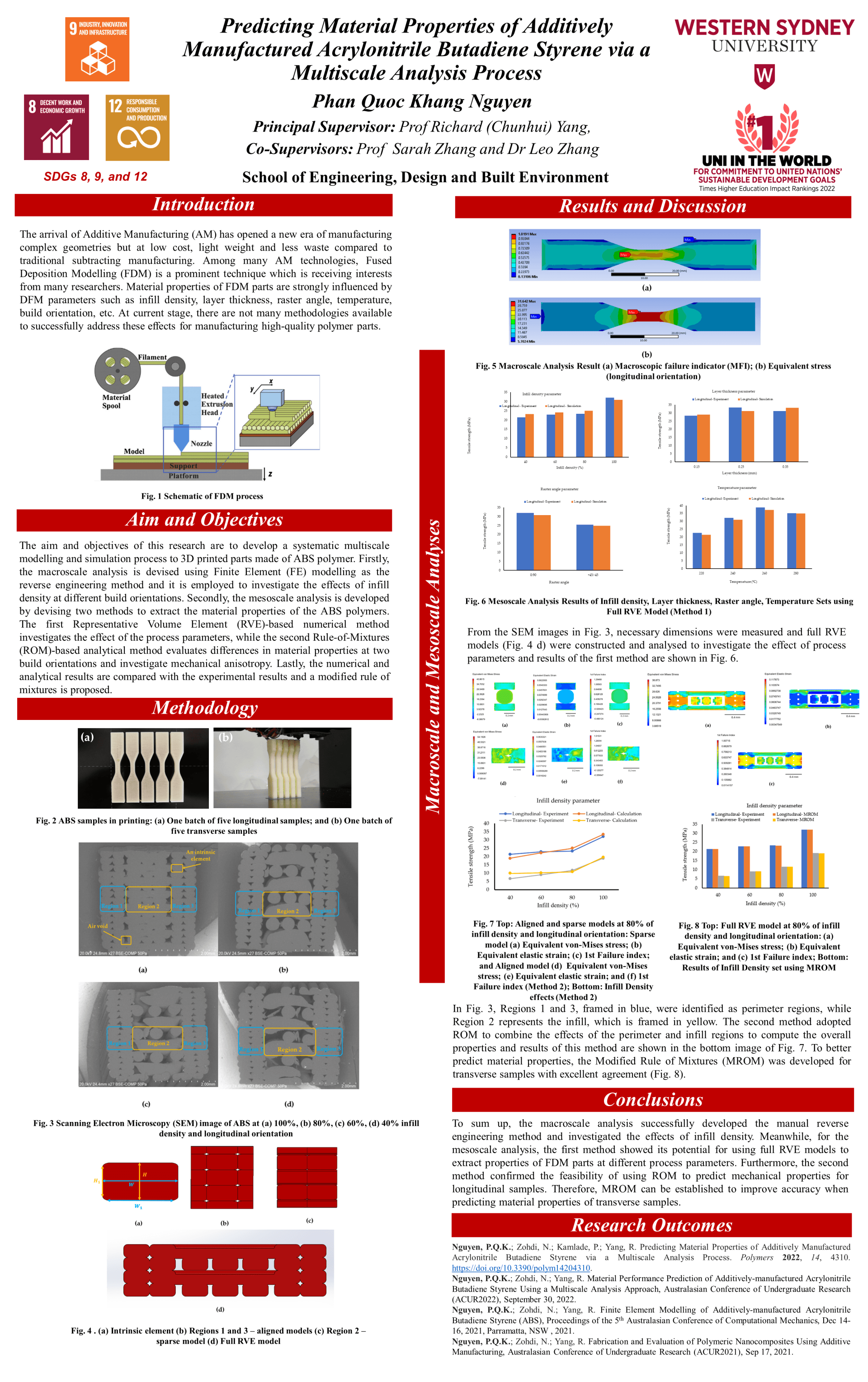

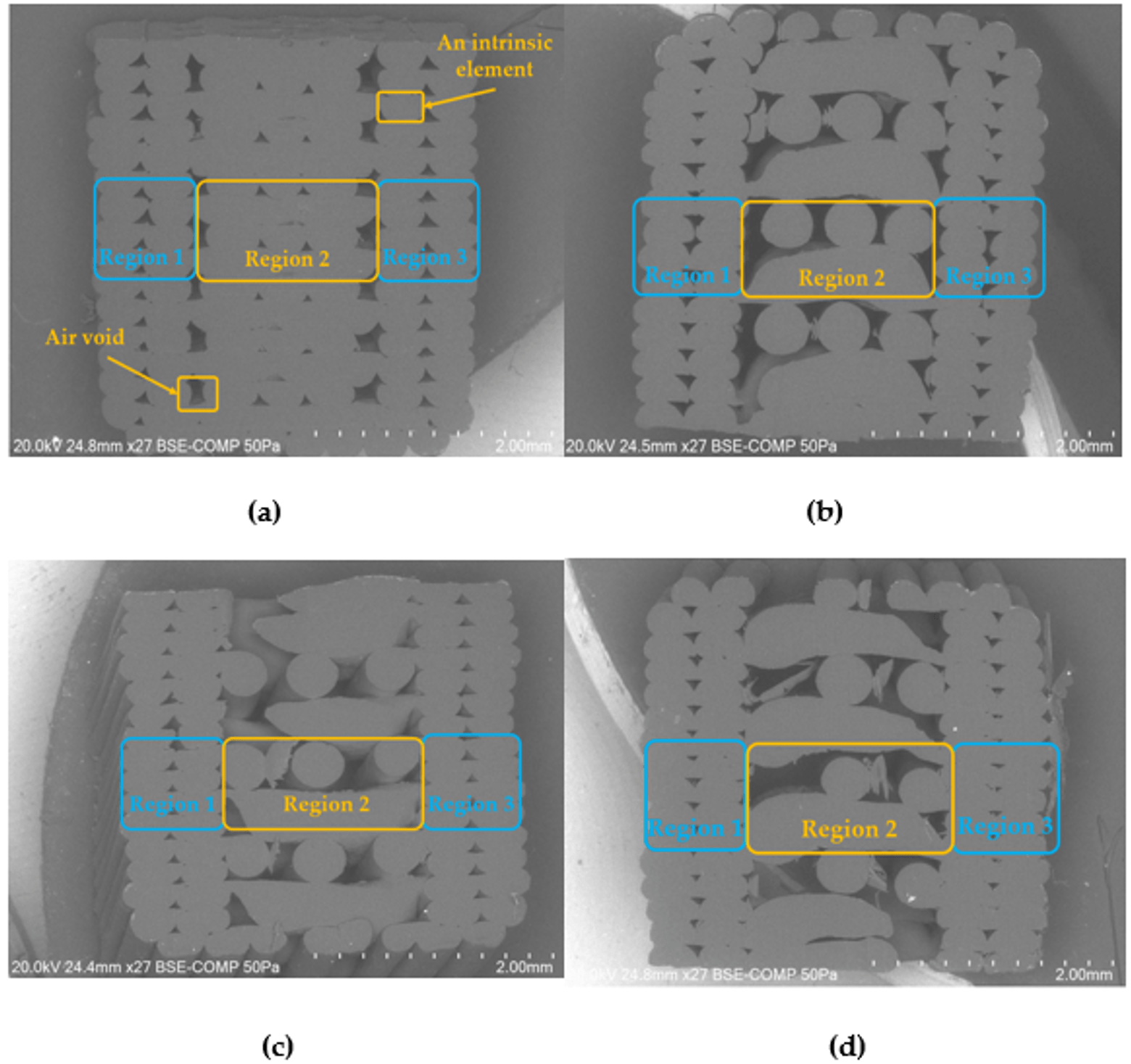

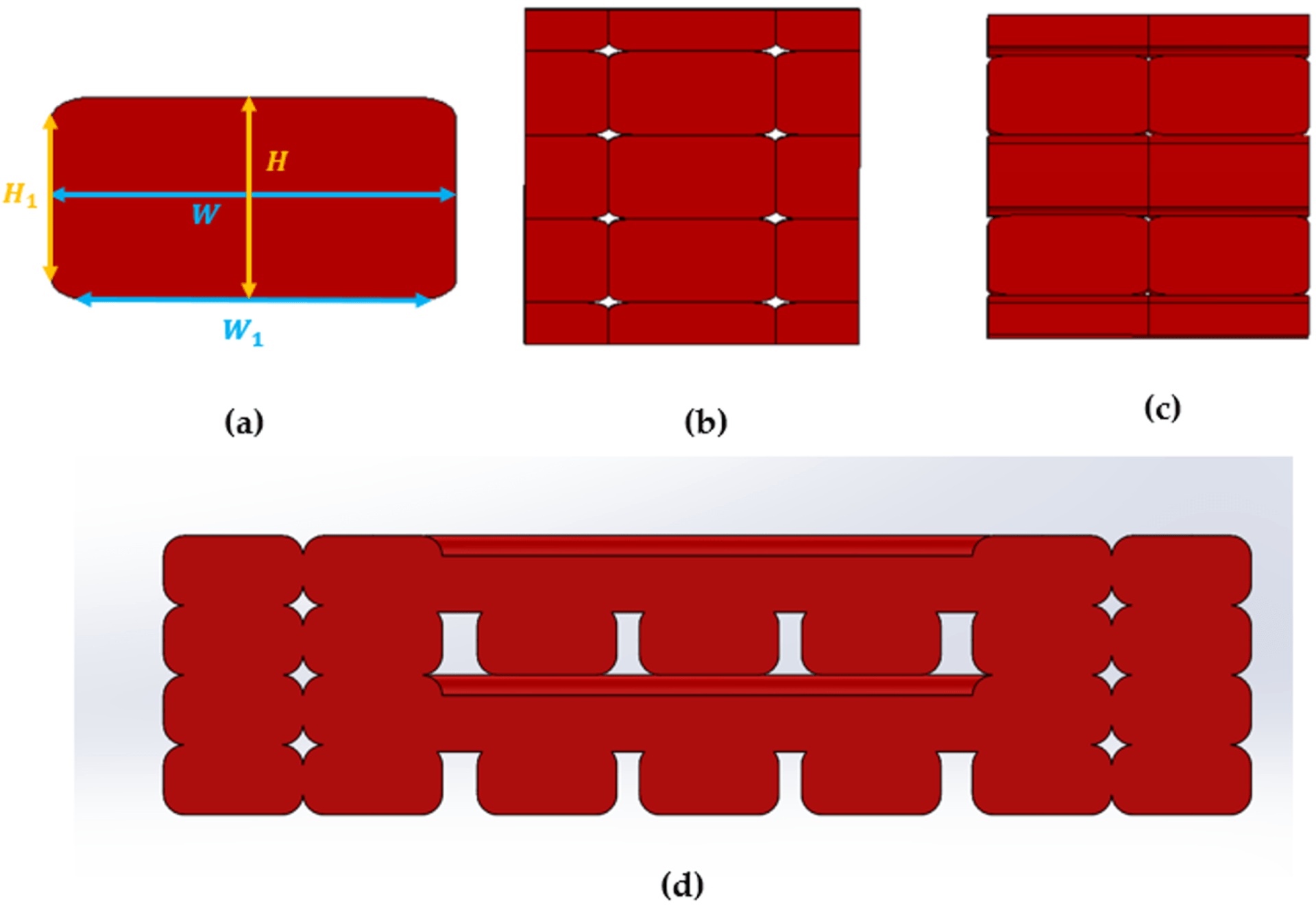

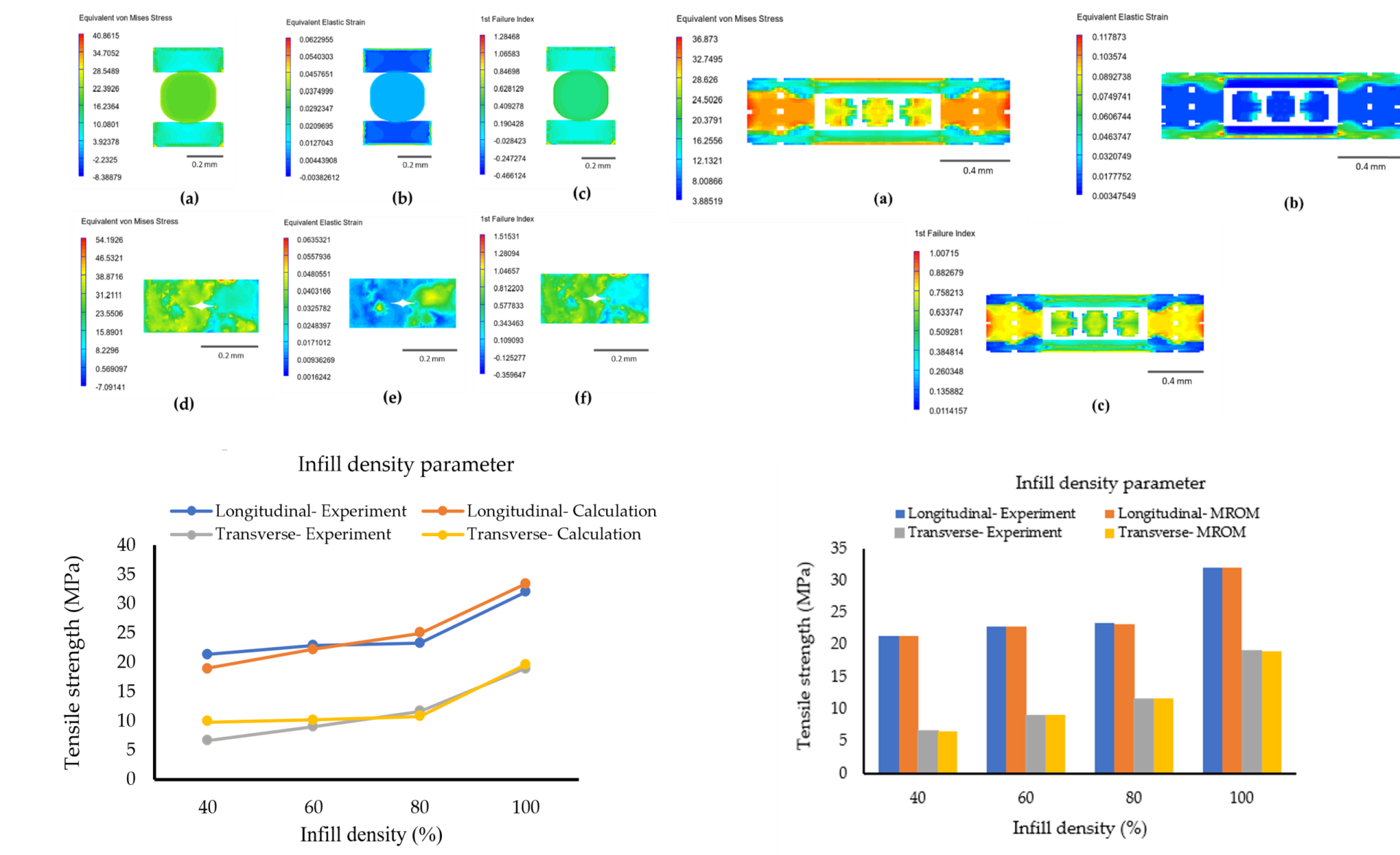

Additive manufacturing (AM) has inherent mechanical strength inconsistencies when the build orientation changes. To address this issue, theoretical models, including analytical and numerical models, can be developed to predict the material properties of additively manufactured materials. Our study develops a systematic finite element (FE)-based multiscale numerical model and simulation process for the polymer acrylonitrile butadiene styrene (ABS). ABS samples are fabricated using fused deposition modelling (FDM) to determine the material properties and mechanical behaviours. For macroscale analysis, good agreement between the numerical and experimental tensile strength of transverse samples proved that the FE model is applicable for applying a reverse engineering method in simulating the uniaxial tension of samples. The FE modelling method shows its capability to consider infill density effects. For mesoscale analysis, two methods are developed. The first method is a representative volume element (RVE)-based numerical model for all longitudinal samples. The second method is analytical and based on the rule of mixtures (ROM). A modified rule of mixtures (MROM) model is also developed, which demonstrates an improvement compared to the original ROM model. The research outcomes of this study can facilitate the AM process of parts in various engineering fields