S M Arifuzzaman

Higher Degree Research

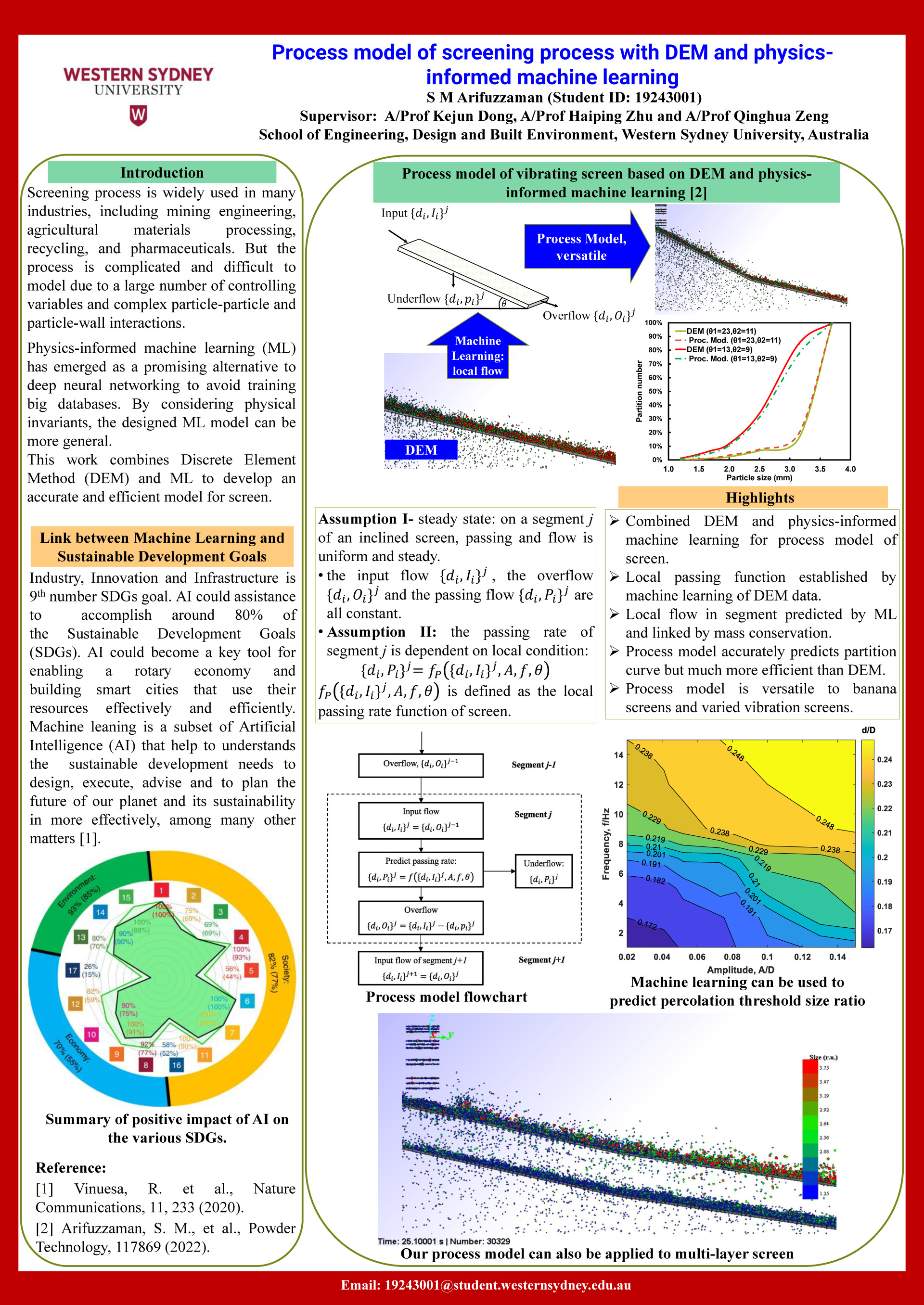

Particle-scale Numerical Study on Screening Processes

Particle screening is one of the most commonly used unit operations in various industrial processes for the classification of particles according to their sizes, such as in mineral processing, pharmaceutical industries, food, plastics, recycling and agricultural industries. The design, control and optimisation of screening operations are important to the performance and profitability of the whole processing industry. In this study, a comprehensive literature review is conducted on different industrial screens. Their differences in geometry, operational conditions and applications are compared. In particular, the performances of these screens are found to be not only dependent on the screens, but also very much dependent on the properties of particles they handle. These properties include particle shape, particle size distribution, and mechanic and surface properties. Therefore in the present industrial screening processes, the largely used macroscopic models cannot be general to different kinds of particles. This is because the dynamic characteristics of granular particles are very complicated due to the complex interactions between individual particles and their interactions with screens. To overcome this deficiency, numerical simulations based on the discrete element method (DEM) have been increasingly used in the study of screening processes. Though the experimental studies are costly, and conditions not easy to control. On the other hand, DEM studies help understand the complicated dynamics of particles flow at particle-scale; generate data for modelling; evaluate screen design. Limitation of DEM: time-consuming due to high resolution in space (particle-scale) and time (small time step to accurately capture each collision). GPU and parallel computation have significantly improved speed. Yet for a large number of particles, DEM simulation is still time consuming. To develop a process model for percolation of particles, inclined, multi-deck and multi-layer screens by the combination of DEM, ANN, and Machine Learning, which can be used for smart design and control.